Digital Supervisor Toolkit — Transforming underground culture from reactive data entry to proactive safety leadership

B2B | Brand | Information Architecture | Product Vision & Strategy | Stakeholder Aligmnent | Qualitive User Research | Testing & QA | Service Design | Product Design

Product

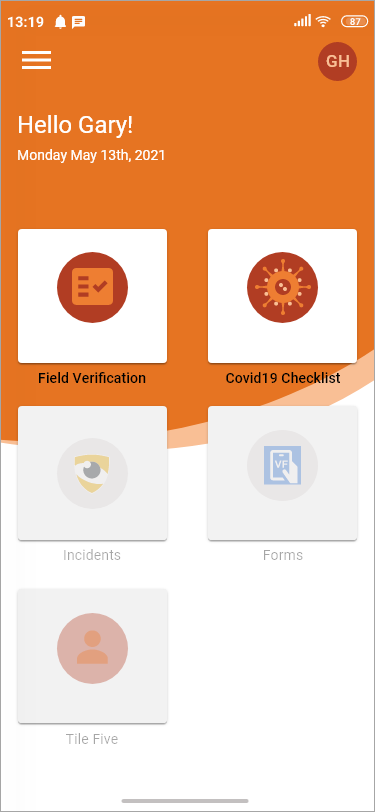

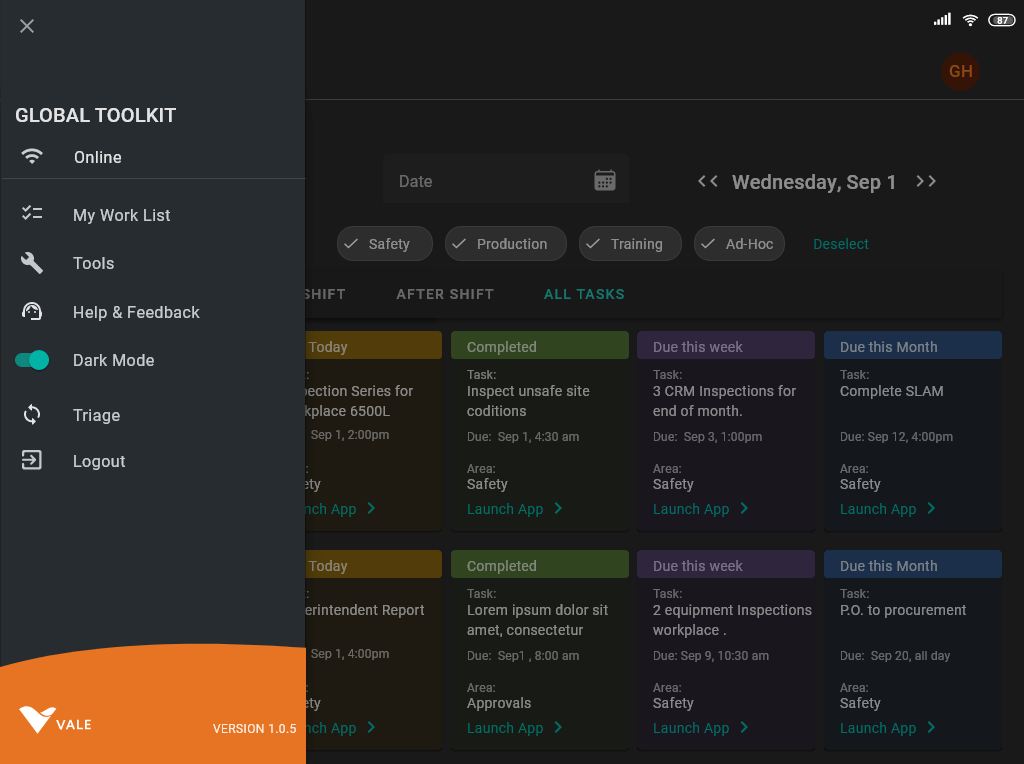

Digital Supervisor Toolkit An offline-first super-app designed for 1,200m underground. It consolidates fragmented tools into one streamlined workflow, featuring mask-ready facial ID and a safety-critical “Dark Mode” for pitch-black environments.

Problem

Despite existing digital initiatives, supervisors were still struggling. While the business knew supervisors lost 42% of their time, high-level data failed to explain why or how that time was lost.

Primary end user

Supervisors

Secondary end user

Front-line workers, Superintendents & Leadership

Client

Vale S.A. A global leader in mining and the world’s largest producer of iron ore and nickel. With $38B revenue and 120k workforce, operations are massive, complex, and high-risk.

My role

Service Design, Researcher & Lead UX Designer.

Team

Product Manager, Canada Stakeholders, Developers, Architect, Global Affairs team.

Timeline

8 months

Outcomes

↓ 75% Reduced pre-shift prep time from 2 hr to <30 min

↑ 68% Adoption in 3 months

↓ Eliminated the need for manual data triplication

Context & Problem

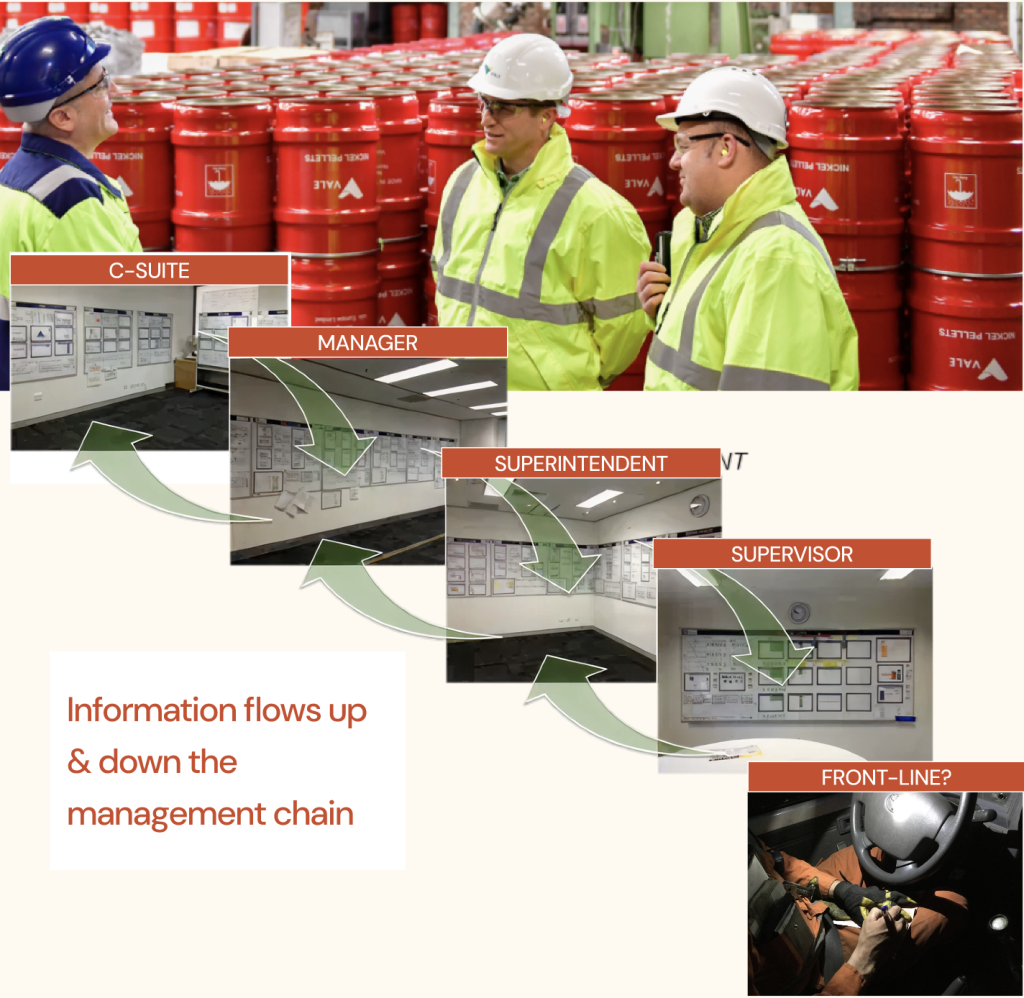

Vale launched the “Digital Supervisor” initiative to modernize a disconnected ecosystem and bridge the critical data gap between underground supervisors and surface leadership.

Business Goal

- The Vision (Real-Time Visibility): Leadership aimed to implement live, real-time dashboards to gain instant visibility into underground operations and streamline decision-making.

- The Metric: Data indicated supervisors were losing 42% of their shift to administrative “firefighting,” pulling them away from safety leadership.

- The Objective: Equip supervisors with a unified “Toolkit” integrating pre-shift, in-shift, and post-shift tasks to shift the culture from reactive data entry to proactive safety management.

The Real Problem

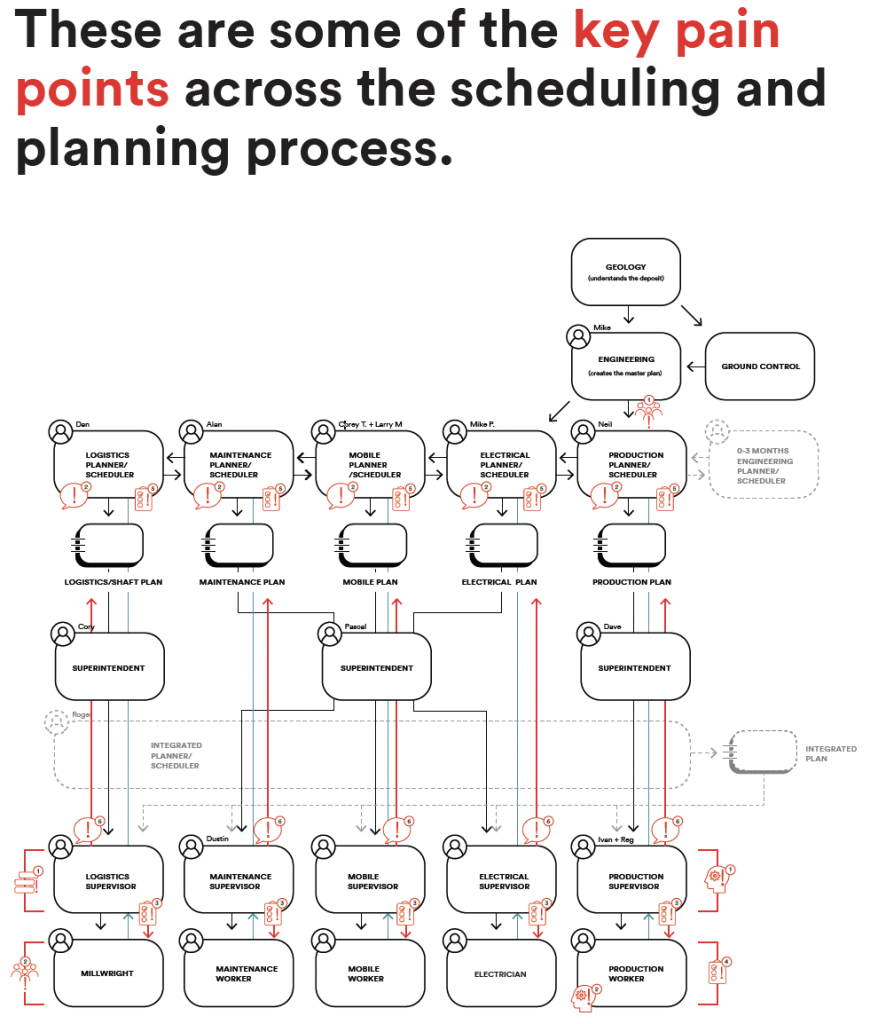

Granularity Gap

Despite existing digital initiatives, supervisors were still struggling. While the business knew supervisors lost 42% of their time, high-level data failed to explain why or how that time was lost.

Problems:

Frontline Blindspot

Inherited research ignored the critical dependency on disconnected frontline workers who feed data manually to supervisors.

Real-Time Fallacy

This blindspot obscured a fatal flaw: “Real-time” dashboards were impossible in a mine with unstable wifi connectivity and not inaccurate data.

Cognitive Overload

Supervisors were forced to act as “human middleware,” bridging paper logs and isolated digital tools. The friction of context-switching across fragmented interfaces was the true efficiency killer.

RESEARCH & DISCOVERY

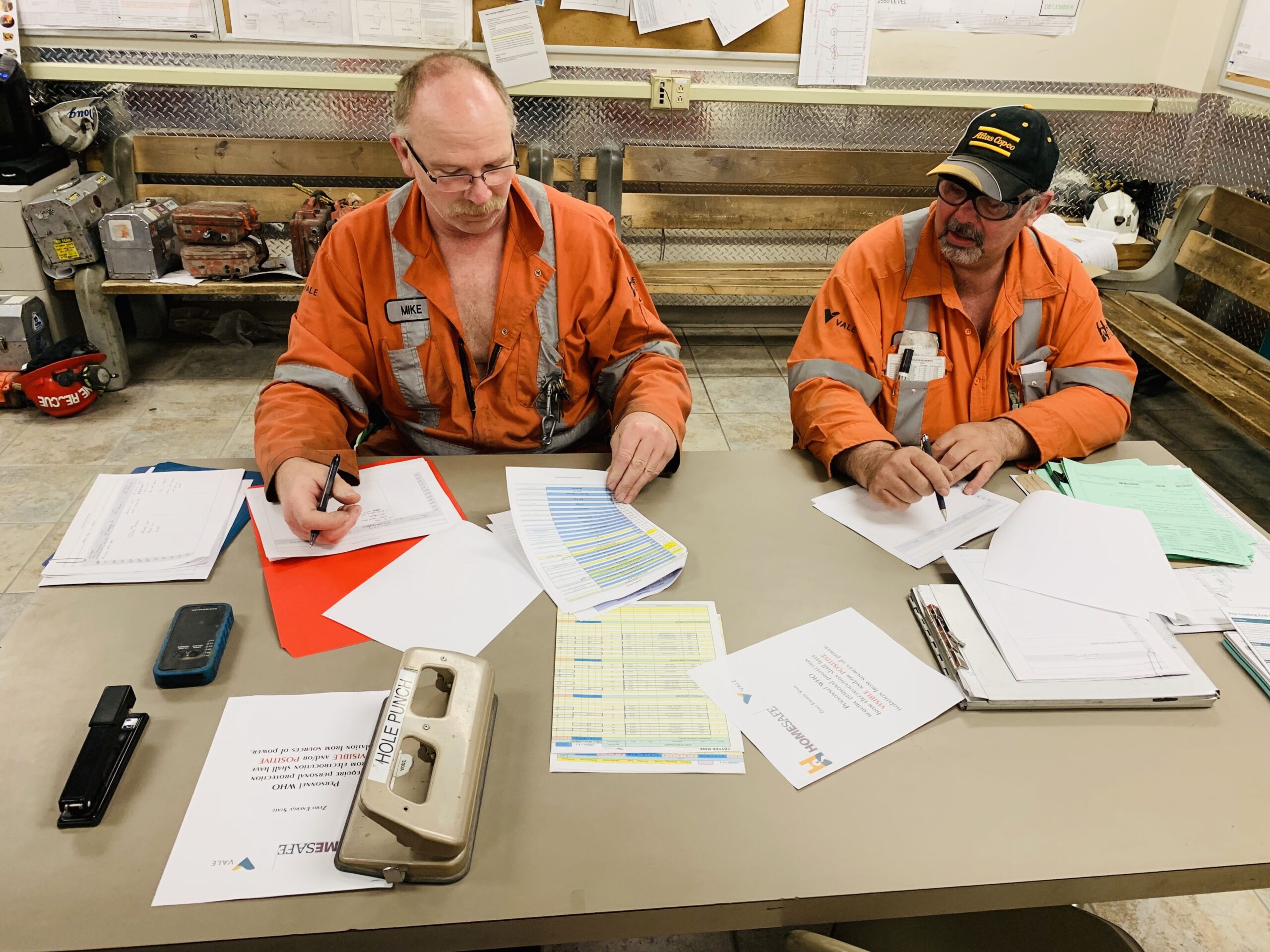

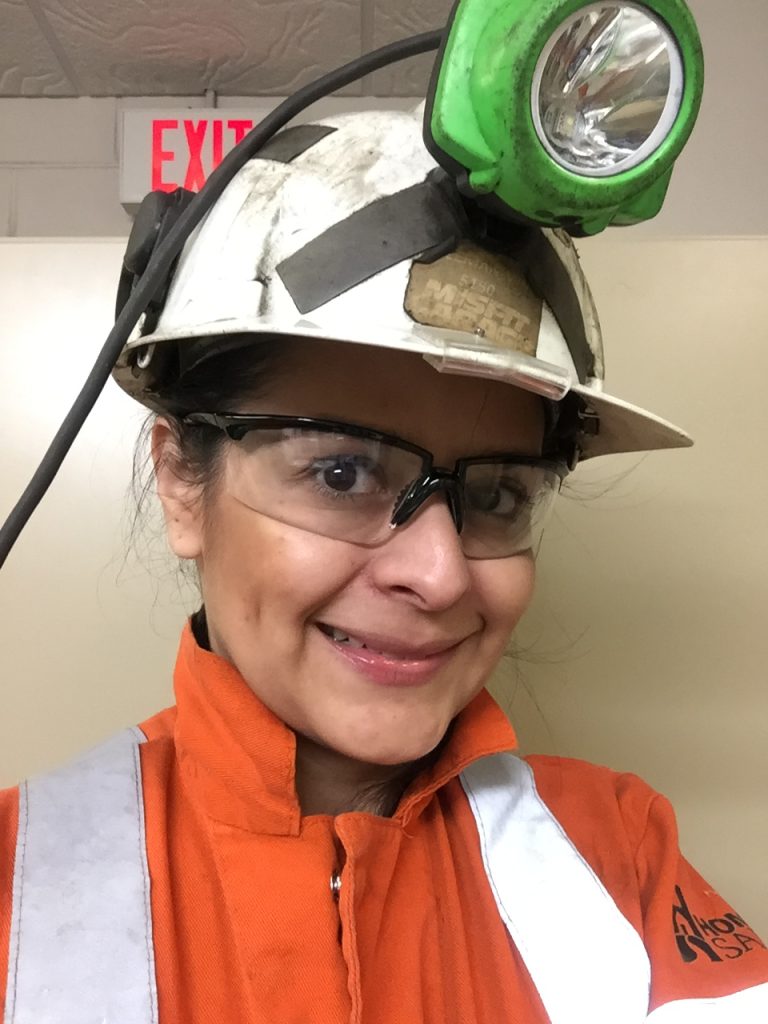

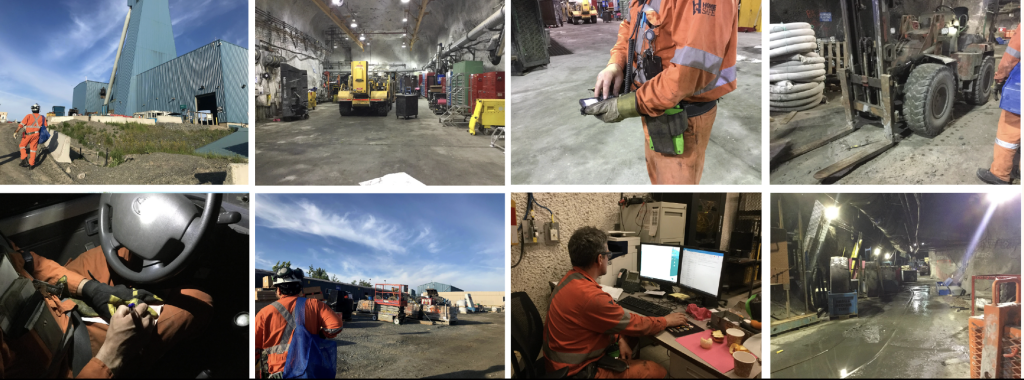

Descending 1,200 m underground to get granular

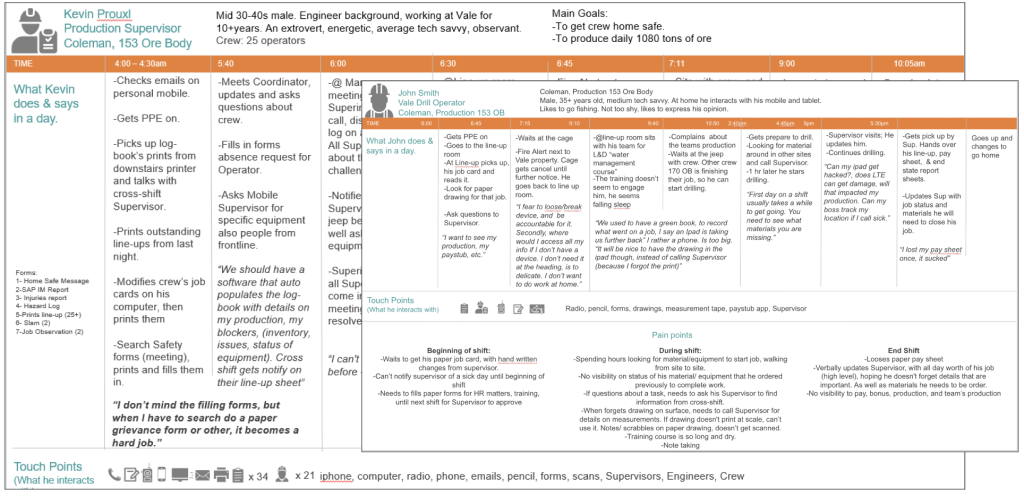

Day in the life

To understand the disconnect between surface-level planning and underground reality, I moved beyond the boardroom. I conducted a 3-week ethnographic study, descending 1,200 meters underground to shadow 12 superintendents, supervisors, and operators (the missing piece) across shifts, across 3 mines in Ontario.

“If I had to do less paper work, I will spend more time out with the guys… now I spend 75% of my time doing paper work.”

— Sebastien Morrissette, Electrical Supervisor

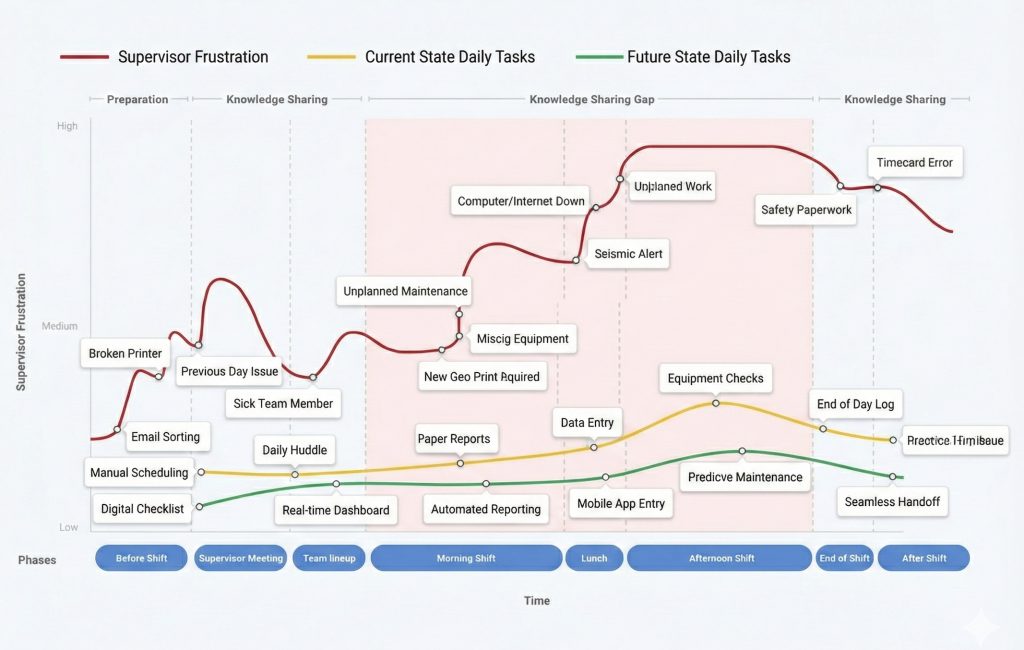

The research provided a granular, minute-by-minute breakdown of the “Day in the Life” for multiple personas including front-line workers. Our research debunked the assumption that supervisors just needed “better forms.” It revealed a broken workflow dictated by physical constraints.

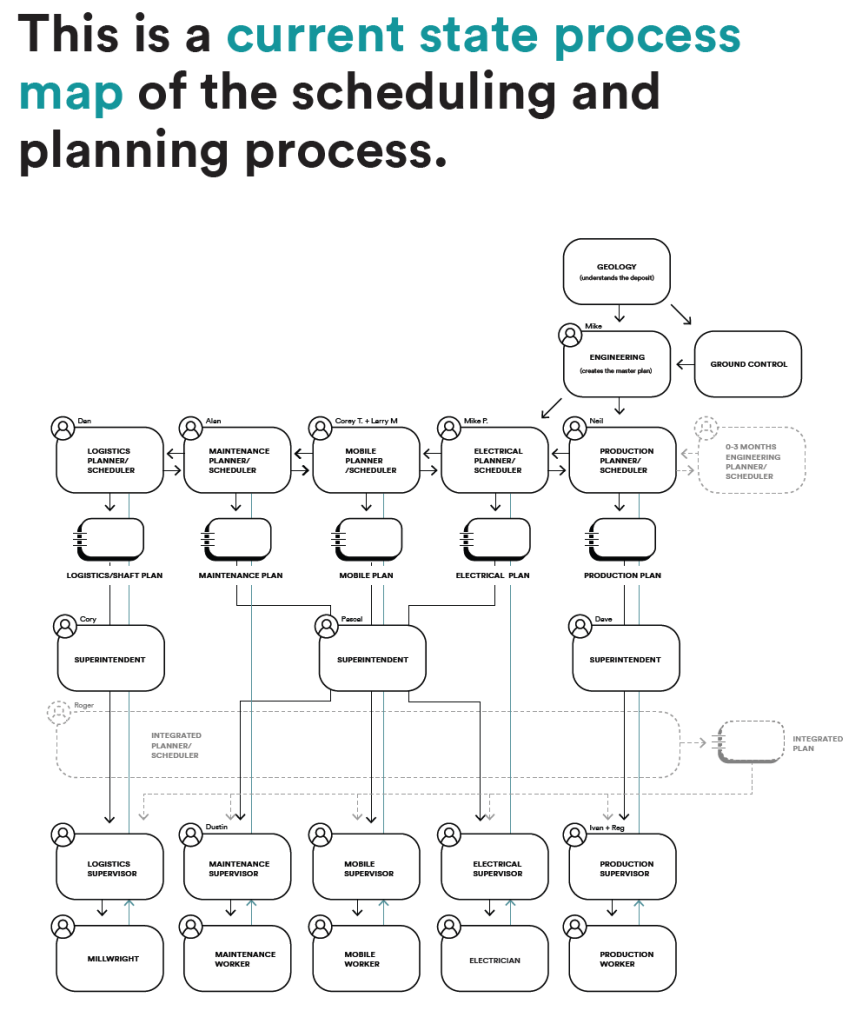

Definition & INTEGRATION

6 strategic areas of friction

Synthesizing the journey maps from the mines, we categorized the pain points into 6 strategic themes to guide the Digital Transformation.

- Technology & Systems

- Communication & Transparency

- Alignment & Prioritization

- Responsibilities & Resources

- Safety & Compliance

- Equipment & Maintenance

The “Day in the Life” provides granular data across the shift Pre-shift (4 am), In-shift (7 am), and Post-shift (3:30 pm).

PROTOTYPE & VALIDATE

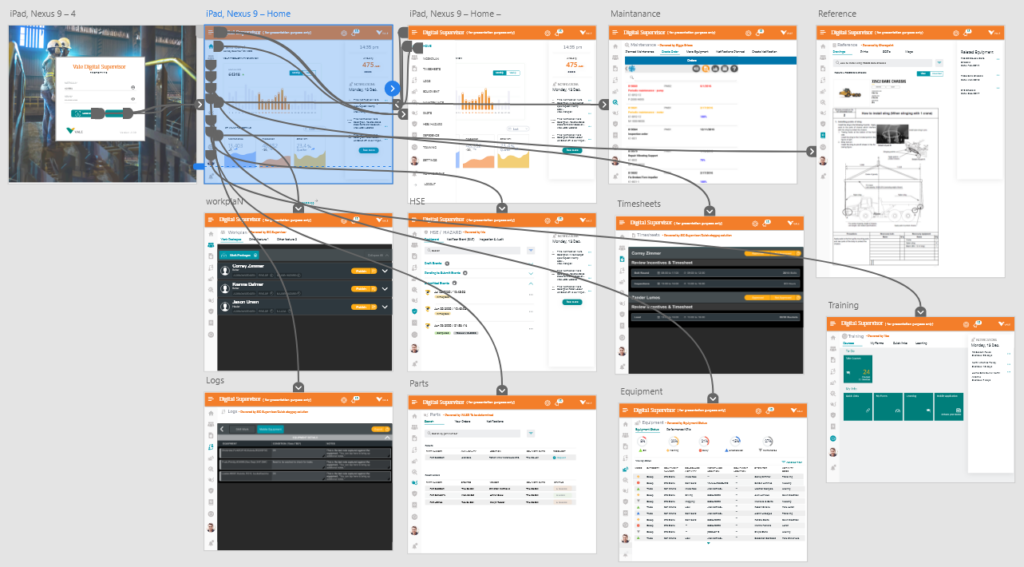

We moved from building “another app” to building an Integration layer (The Toolkit).

- From Reporting to Assisting: We reframed the tool from a “Tracker” (Surveillance) to a “Digital Assistant” (Help) to ensure adoption.

- Offline-First Infrastructure: The Toolkit brings tools to the face, syncing only when the supervisor surfaces, solving the connectivity gap that previous “real-time” dashboards ignored.

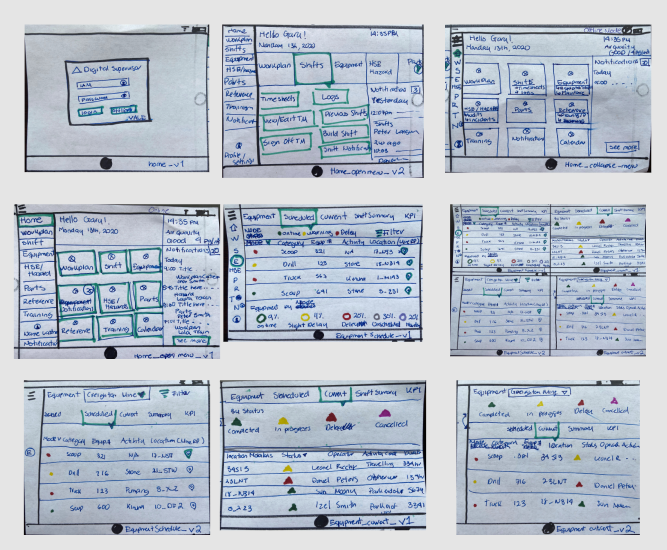

De-risking development through co-design

We had build a partnership with Supervisors, and we were able to tested interactive prototypes to validate design and iterate before development.

PROTOTYPE & VALIDATE

The Pilot: Validating under pressure

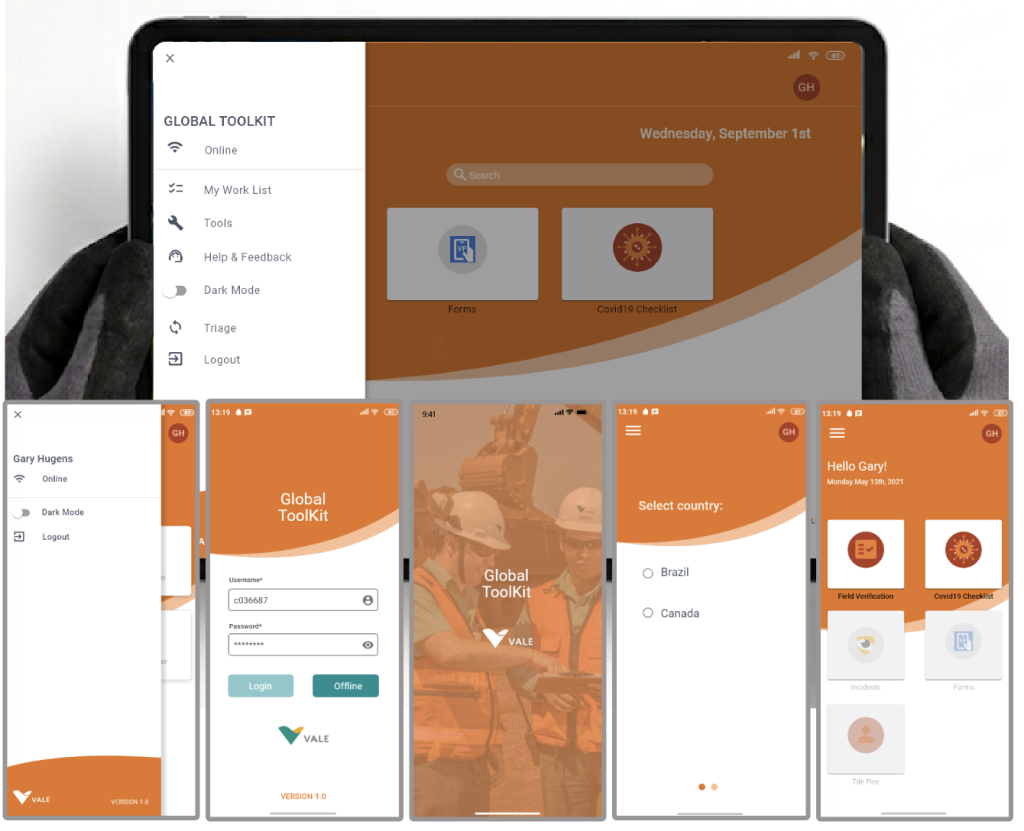

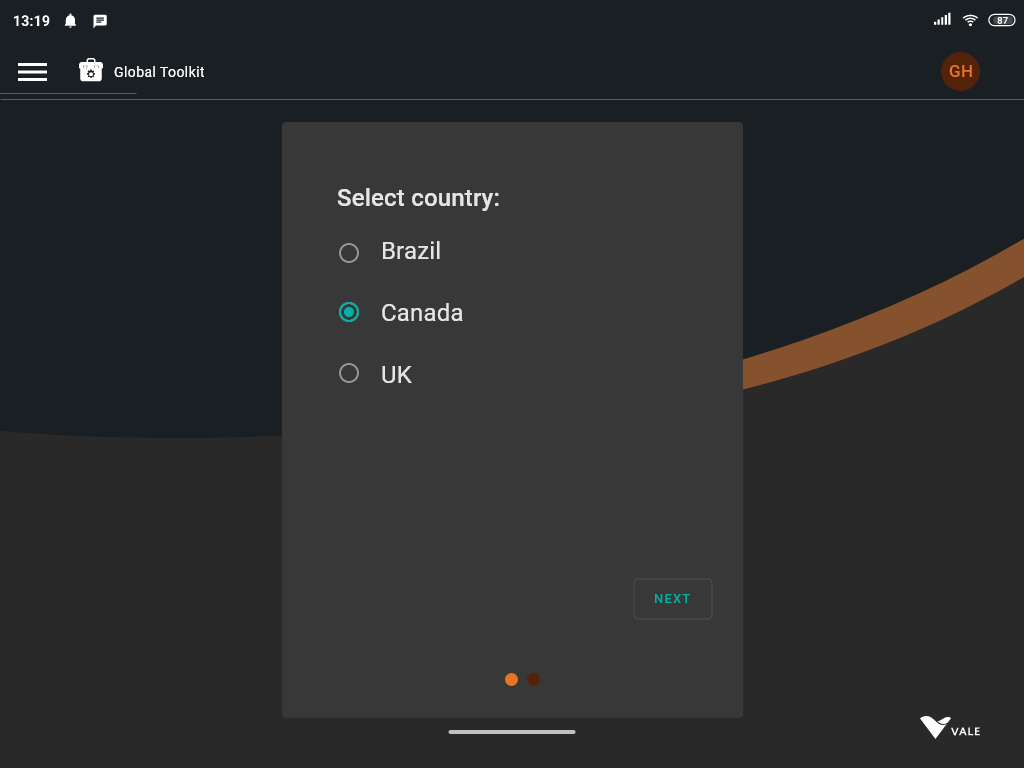

As the 2020 pandemic unfolded, Vale faced an urgent challenge: maintaining production across 9 Ontario mines while ensuring workforce safety.

Strategic Pivot (MVP 1):

We shifted focus from “efficiency” to “survival.” We deprioritized management operations and Microsoft Teams integration to focus exclusively on a COVID self-screening tool (ValeForms).

Feature Prioritization:

To remove barriers to entry for thousands of workers, we prioritized Single Sign-On (SSO) and solved the technical challenge of Face Recognition for mask-wearing users.

Field Validation (The “Light Mode” Failure):

Stakeholders deprioritized Dark Mode to speed up delivery, but field testing proved “Light Mode” physically blinded supervisors underground. This critical safety finding overturned the decision, immediately reinstating Dark Mode as a non-negotiable requirement.

SOLUTION

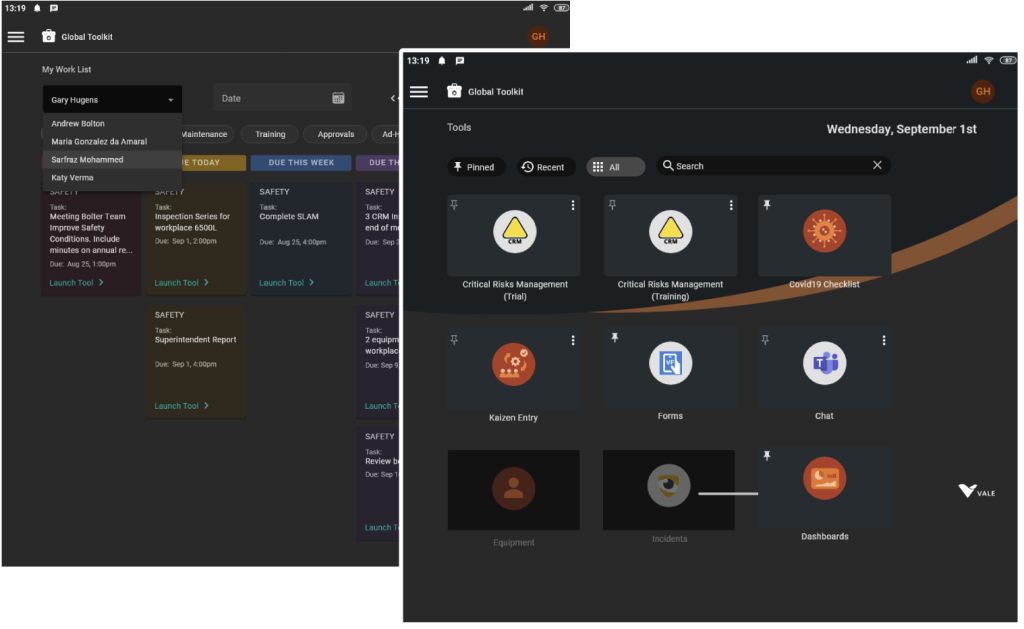

A unified mobile ecosystem that integrates with existing back-end systems

Offline-First Architecture: Enabled supervisors to capture data at the face (1,200m deep) One portal for all pre-shift, in-shift, and post-shift tasks.

Single Login-On (SSO): Consolidated 5+ logins into one portal, directly addressing Gary’s frustration with “too many interfaces”.

Digital Handover: A standardized digital log replaced handwritten notes, ensuring the next shift had accurate context.

Asset Tracking: Integrated visibility for equipment, directly solving the “lost fan” issue Kevin highlighted.

IMPACT

Started as a request for a reporting app evolved into a comprehensive digital ecosystem that empowers the frontline workforce to work safer and smarter.

Reduction

User percieved value

Reduced pre-shift prep from 2 hours to <30 minutes.

Scaled

Data Silos

Scaled from a pilot to 10+ global products serving 30,000 users.

Compliance

User percieved value

90% digital adoption for COVID screening.

Cut Cost

Data Silos

Reduced support tickets by 65% and training time by 83% (via the ValeForms module)